Ribbon Blender Suppliers in India

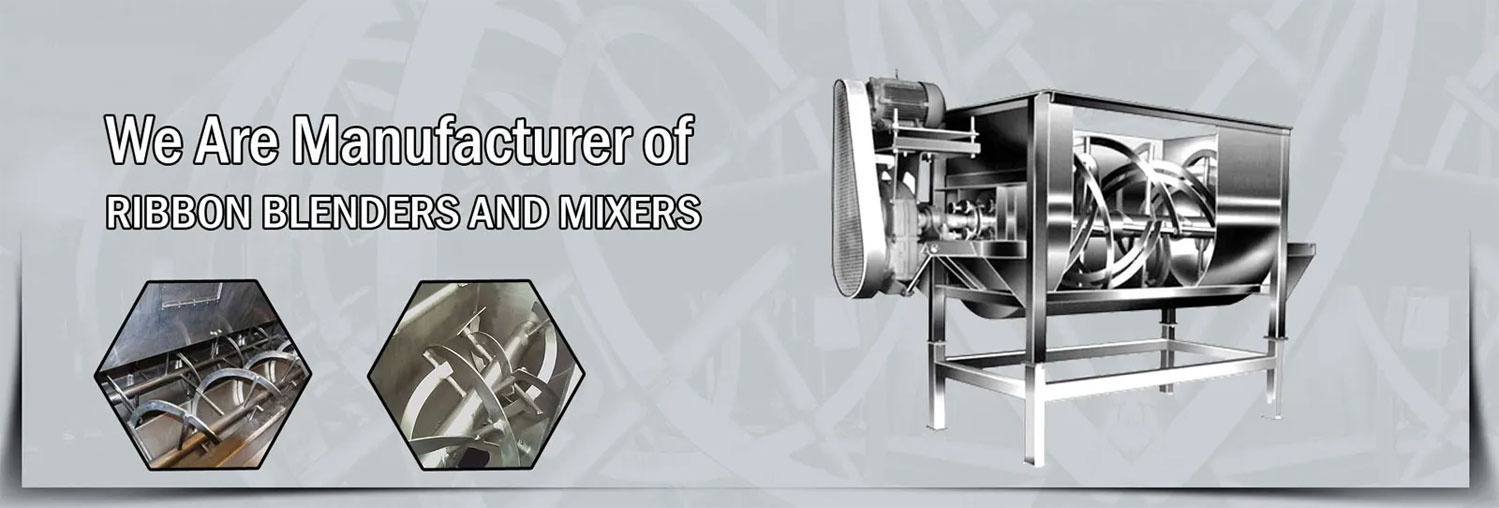

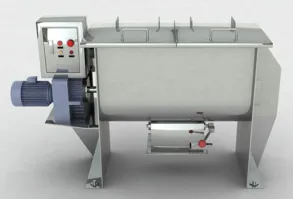

We manufacture large, specialized High Capacity Ribbon Blenders that are used for mixing materials in different applications. We are leading manufacturer and supplier of Ribbon Blenders that are frequently used for Drying, Pigments cake mixes, instant drink blends. These blenders are large trough-shaped device with rounded metal strips twisted like ribbons.

Our broad range of Large Scale Ribbon Blender is made of stainless steel 304, in compliance with all cGMP / cGEP standards and versatile to function as blender, paste mixer, vacuum dryer. These are based on a proven campaigner structure that provides a triple mixing action ensuring fast, efficient blending.

We also manufacture Ribbon Mixer for Dry Powder, Ribbon Blender for Liquid Coating And Drying, Paddle Blender for Dry Powder Blending, Nauta Mixer, Vertical Cone Screw Blender/Dryers and Pharmaceutical Ribbon Blender in many cities, states of India and in foreign countries like Africa, Dubai, Europe and New Zealand.